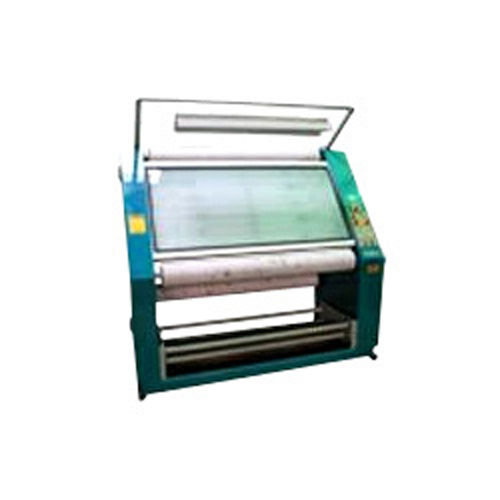

Fabric Inspection Machine

MOQ : 1 , , Unit

Fabric Inspection Machine Specification

- Installation Type

- Floor Mounted

- Inspection Table Material

- High Quality Steel Frame with Polycarbonate Surface

- Optional Features

- Tension Control, Print Mark Sensor, Barcode Scanner

- Edge Alignment System

- Automatic Edge Control

- Maximum Fabric Roll Weight

- Up to 100 kg

- Machine Type

- Automatic/Manual Fabric Inspection Machine

- Lighting System

- Integrated LED Illumination

- Roll Diameter Capacity

- Up to 500 mm

- Fabric Feeding Mode

- Center or Edge Feeding

- Counting System

- Digital or Mechanical Meter Counter

- Noise Level

- Less than 70 dB

Fabric Inspection Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Delivery Time

- 7 Days

About Fabric Inspection Machine

Fabric Inspection Machine that we are offering is an advanced mechanical system designed for the inspection of fabric. It detects all visual and printing defects. It is also suitable for the re-rolling. It can effectively check and improve defects of fabrics in open and tubular form. It is equipped with the variable speed electric motor that assists in moving the fabric upwards and downwards. Owing to its top-notch quality and performance, we are experiencing a huge demand for the Fabric Inspection Machine in the market.

Specification:

- Variable speed

- Dynamic nature

- Motorized drive for moving fabric upwards or downwards by hand or paddle switch

- Ideal to mend or check fabrics in open or tubular foams

- An adjustable former to re-roll the fabric in different widths

- Standard Head Sizes: 48, 60, 72, 90, & 120 Inches working width models

Superior Fabric Inspection Performance

Equipped with a reliable digital or mechanical meter counter and automatic edge alignment, this machine enables efficient and precise fabric inspection. The integrated LED lighting system enhances visibility, helping operators spot even minor defects or inconsistencies. Designed for a broad range of fabric types, it supports both automatic and manual modes for flexibility in operation.

Rugged Construction and User-Friendly Design

Built with a steel frame and durable polycarbonate table, the machine withstands rigorous use in industrial environments. Center or edge fabric feeding and floor-mounted installation make it adaptable to diverse setups. Optional features like tension control and barcode scanning offer enhanced customization, accommodating distinct processing requirements for garment and textile industries.

FAQs of Fabric Inspection Machine:

Q: How does the automatic edge alignment system benefit fabric inspection?

A: The automatic edge alignment system ensures fabrics are maintained in the correct position during inspection, reducing the risk of alignment errors and fabric waste. This leads to more accurate defect detection and improved overall inspection efficiency.Q: What fabric types and sizes can the machine accommodate?

A: This fabric inspection machine supports rolls with a diameter of up to 500 mm and a maximum weight of 100 kg. Its sturdy design and adjustable feeding modes allow it to handle various fabric types, from lightweight textiles to heavier materials.Q: When should I use the optional tension control and print mark sensor?

A: Optional features like tension control and print mark sensor are recommended for operations requiring precise fabric tension management or print alignment, such as in printing or high-quality fabric production. These options enhance inspection accuracy and streamline production workflows.Q: Where is the machine installed and how does its design support stability?

A: The inspection machine is floor-mounted, providing solid support and stability even when handling heavy or large fabric rolls. Its steel frame construction and balanced design minimize vibration and ensure smooth operation in industrial settings.Q: What is the process for inspecting fabric with this machine?

A: Operators load the fabric onto the inspection table, choose between center or edge feeding, and initiate inspection using either automatic or manual controls. The integrated LED lighting, digital/meticulous counter, and edge alignment system work together to deliver accurate and efficient inspection results.Q: How noisy is the machine during operation, and what measures reduce sound levels?

A: The machine operates at noise levels below 70 dB, making it suitable for factory environments where low sound output is essential. Its robust construction and efficient components help minimize operational noise, ensuring a comfortable workspace.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS